Ensuring reliable power delivery to the ground is as crucial as generating power itself. In our planning discussions with customers, we prioritize understanding their expectations for the car. It all begins with a conversation about the desired performance and outcomes.

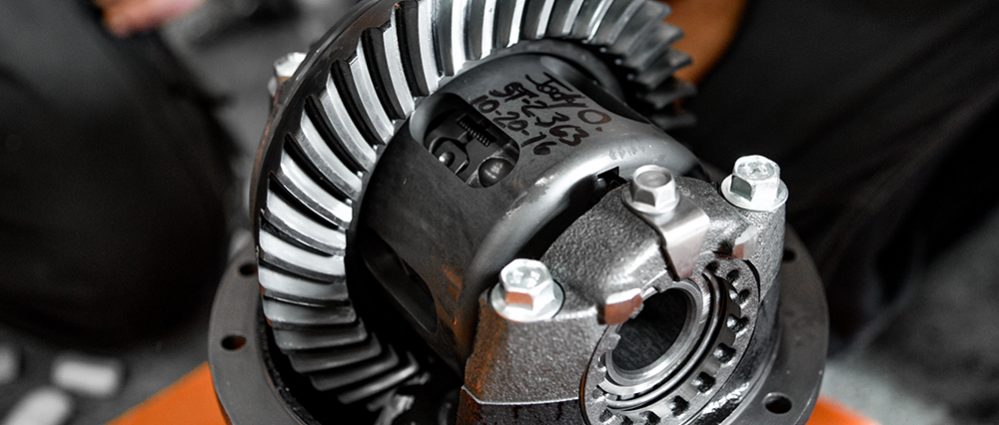

Using that information, we can select the appropriate prop shaft and differential setup, whether it’s a single piece or split prop shaft, a 1 or 2-way LSD, and determine the optimal gearing ratios. This takes into account the power and strain levels for a tailored solution that meets the specific requirements discussed.

When revising and rebuilding differentials, the process kicks off with a specification check. This ensures that the internal components of the differentials are not excessively worn, providing a solid foundation for the rest of the work.

At this stage, we have the option to disassemble the differential down to its bare case and apply a new coating if desired. The differential is then meticulously reassembled with the correct specifications to meet our customers’ requirements. We document the entire process with both photos and detailed values.